Hot products

Tel:0086- 166 5317 7104

E-mail:sales01@lanbaopm.com

In practice triplex pumps have the following advantages:

The triplex pump provides a more even delivery so that discharge variations are about half those of a duplex pump. This provides a longer life of pump parts, hoses, etc.

The total weight of a triplex pump is approximately 70 % of that of a duplex pump with the same capacity and it also requires less space.

Triplex pumps are more accessible than duplex pumps and consequently, maintenance is faster and cheaper.

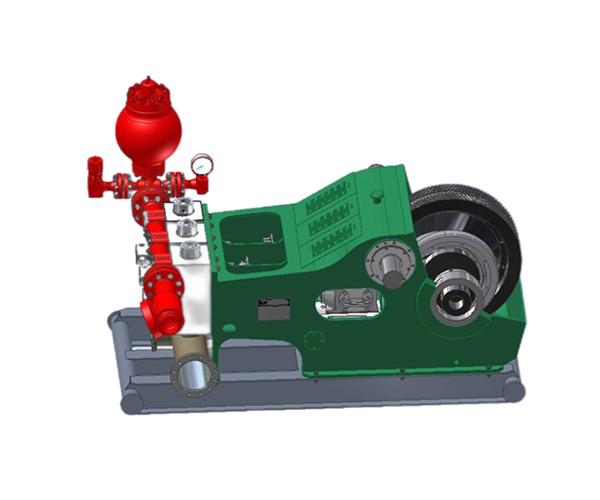

Design features:

pump power and pressure on each piston diameter allow forced drilling practices;

forged fluid ends made of high-strength alloyed steel;

ion nitriding of the gear transmission;

hydraulic seal of the cylinder and piston assembly;

double-chamber seal of the slide block rod for excluding oil leakage from the case, its contamination with drilling mud;

lubrication of reduction gear through two systems:

-pressure lubrication with automated maintaining of constant pressure in the oil line;

-gravity oil system lubrication from storage trays;

safety valve of the locking device;

drive transmission at any side of the pump or at the both sides;

suction and discharge headers for pipes connection from both sides.

3NB series mud pump basic parameters:

Model | 3NB500C | 3NB1000C | 3NB1300C | 3NB1600 |

Power | 368 (500) | 735 (1000) | 956 (1300) | 1176 (1600) |

Rated Speed | 95 | 110 | 120 | 120 |

Stroke | 254 | 305 | 305 | 305 |

Gear Ratio | 3.82 | 3.833 | 3.81 | 3.81 |

Max Pressure | 30 | 35 | 35 | 35 |

Max Liner Sizes | 160 | 170 | 180 | 190 |

Suction Nozzle | 254 | 305 | 305 | 305 |

Discharge Pipe | 100 | 100 | 100 | 100 |

Dimensions | 4220×2640×2430 | 5170×2809×2530 | 5010×1942×1918 | 4450×2850×2077 |

Weight | 15940 | 21450 | 23000 | 29700 |